|

| Mt Graylock, MA |

In keeping with the upcoming Super Bowl, Marty, Stic and I did a blitz tour of New England layouts last weekend and took in the train show at the Big E. And we didn't even get tackled. I can report that New England is in a fever pitch and is ready for the big game, but for this weekend, we could care less as we saw and operated on some great layouts.

The weekend began with a fumble as American Airlines only realized they were short a pilot to fly our plane after they dragged all the passengers out to the aircraft on a shuttle. Marty volunteered to quarterback the flight, but since he's only ever piloted a Navy LST, the airline took a time out instead. The airline eventually got us to Hartford after one hour of booth review and we began the epic weekend.

|

| Marty and Jim (l to r) |

First down was Jim DuFour's Cheshire Branch layout in the far suburbs of Boston. It depicts a Boston and Maine branch line in the 1950s. It is a jewel of a layout, with heavy prototype basis. We got to run some engines and they performed flawlessly. Jim has some of the best sounding engines too. He and his technician helpers have been able to program the sound systems for very realistic sound effects. We met a bunch of neat folks at Jim's including George Corey, a 92 year old railfan that has amazingly vivid memories of the B&M steam operations, friends from Canada (who were captivated by the fact that Stic was once a professional hockey player) and the staff of MRH.

|

Marty, Chris and Stic (l to r) . Chris is showing us his New Haven

Library and artifact collection on the second floor of his home.

The layout fills the basement |

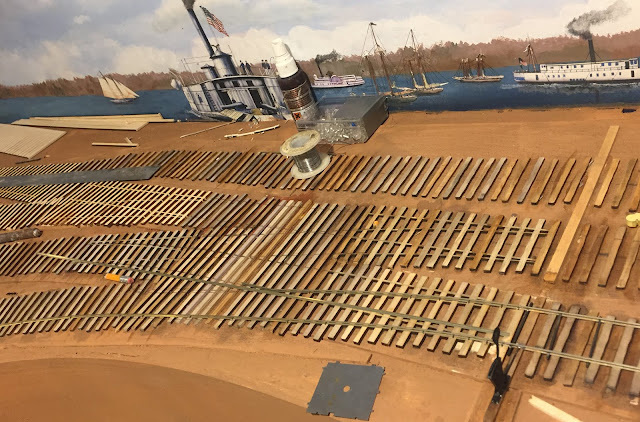

After a few delightful hours with Jim, we threw a deep bomb on second down and headed south to the Connecticut shores of the Long Island Sound to operate on Chris Adams's Valley Line. He models a New Haven branch line that happens to run about 50 yards behind his house, though now as a tourist line. The prototype railroad was not running, but we made up for it by running nearly a full set of downs on the layout. Chris's layout is strictly prototype based. It is still being sceniced in some areas, but the operations were great. Lot of switching and interplay between trains. I got a choice job - the Valley Local. I was lucky to have Pete as my conductor while I handled the throttle. Pete was very capable and we had a great time. The little 2-8-0 we ran was flawless. We also had a great time meeting his regular crew, several of whom said they are readers of the blog. Thanks guys. Leave a comment every and now and then to say, "hi".

We were exhausted when we arrived at the hotel in Springfield just before midnight. We punted and went to bed.

|

| Tom Piccirillo (O scale modeler) and Hal Miller at MR Booth. (l to r) |

The next day was the train show at the Big E. It was a huge show spread across 5 buildings. My objectives were to buy needed supplies for the Aquia Line and other projects. I was very successful, even though I did not get to see everything at the show. It was fun to see some old friends, like Tom Piccirillo, and meet a lot of new people, including Hal Miller, editor of Model Railroader magazine. That night we had diner in a restored dinning car at the Steaming Tender Restaurant in Palmer, Massachusetts.

|

Jason's lift our section using linear actuators. There are actually

three actuators, one is not visible in this photo. |

On Sunday we visited Jason Fountain and Neil Schofield's layouts in Charlton, Massachusetts. Both were outstanding layouts. Jason models the Southern New England, one of my personal favorite railroads even though it never existed. His layout includes dozens of craftsman structures arrayed in a very realistic manner. It creates a very believable impression of a New England town and countryside in the steam to diesel transition era. He has a lift-out section that uses three linear actuators that is very impressive and clever.

|

| Jason, Marty, and Stic (l to r) |

|

| Fantastic Mill on Jason's layout |

|

Photo line of model railfan at Neil's layout. That's Don James in the

foreground with the tripod. In addition to being a retired locomotive engineer,

a fantastic modeler, and an Alkem Scale Models customer, Don is

one of Stic's biggest fans. |

Neil's layout is set in the 1980s on CP trunk line in northern Vermont from Wells River to Sherbrooke. After two years of work his layout is about 1/3rd complete, but what he has finished is utterly outstanding. It is hyper-realistic scenery essentially on a narrow shelf. He showed us his layout plans and it looks like it will be an amazing design. I look forward to going back and operating it as it gets further along.

|

| Shot showing some of Neil's realistic scenery |

On Monday we headed northwest from Springfield through some gorgeous Berkshire scenery (see first photo above) to visit Dick Elwell's Hoosac Valley layout. Dick has essentially completed the layout and it is gorgeous. He has hundreds of contest quality craftsman structures on the layout. They are skillfully arranged in a realistic manner and have no whiff of caricature that frequently accompanies these structures. When you stand in the basement you feel like you are in rural New England on a brisk fall day. Thelayout also features operational signals, CTC, sound, and it runs great. Seeing this layout was a real treat. I have to rank it as one of the top layouts I have ever visited.

|

| Stic, Dick and Marty (l to r) |

We returned home safe and sound. All in all a great weekend. Thanks to all our hosts for their hospitality and friendship. We model railroaders are so fortunate to have friends around the world that so generously share their time and hobby with us.

BTW this was post 800 to this blog. There have been over 1.2 million visits.